Production Solutions

Aehr Test Systems provides complete production solutions across your product manufacturing flow to improve yield and reliability.

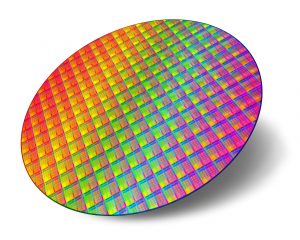

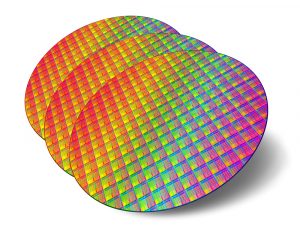

Wafer Level Test and Burn-in Solutions

Single Wafer Test and Burn-in Solutions

The FOX-CP is a single wafer, single touchdown burn-in and test solution for high volume production.

- Lowest test cost per wafer, as more tests move from packaged parts to wafers for stacked die applications

- Industry first Universal Channel Architecture where any channel supports I/O, Power Supply, Clock, PPMU functionality – thousands of resources available for full-wafer testing

- Optimized for DFT, BIST, and high parallelism

- Proven applications include: Full wafer functional, stress, and burn-in test of automotive ICs; low cost full wafer test of discrete or embedded memories;

Multi Wafer Test and Burn-in Solutions

The FOX-XP is a Multi-Wafer System burn-in and test solution for high volume production

- Lowest test & burn-in cost per wafer for complex devices – test up to 18 wafers in parallel in a single chamber

- Uses Aehr Test WaferPakTM Contactors with tens of thousands of pins to contact each wafer for single insertion full-wafer test and burn-in

- Industry first Universal Channel Architecture where any channel supports I/O, Power Supply, Clock, PPMU functionality

- Optimized for DFT, BIST, and Long Test Times

- Proven applications include: Full wafer functional test, stress, cycling and burn-in of Logic, Memory and Photonic devices

- Stand alone and full-automation test cells with integrated WaferPak Handler/Aligners

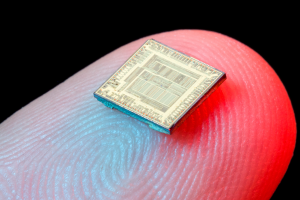

Die Level Test and Burn-in Solutions

The FOX-XP is a highly flexible test/burn-in solution for singulated die and module testing through use of FOX DiePak carriers. An optional automated DiePak Loader is available for loading/unloading devices into DiePak Carriers to increase throughput.

- Accommodate 100s of modules/dice per burn-in/test board

- Address very small die / CSP module pad contact requirements

- Solve module/die socketing challenges

- Measure optical light energy of individual dice/modules

- Maintain tight thermal control of heat generated by device and optical light energy

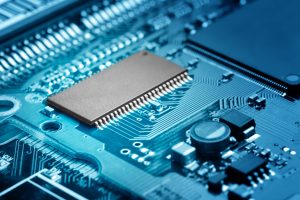

Packaged Parts Test and Burn-in Solutions

The Sonoma and Tahoe Systems are the industry’s most capable test and burn-in platforms for today’s advanced semiconductor devices

- Modular, upgradeable, and scalable test electronics for future-proof capabilities

- High power option up to 2000W per DUT

- Supports production burn-in screening, and HTOL, HTRB, HTGB qualification testing

- Cutting-edge pin electronics for test versatility

- Protocol-aware testing with SPI, I2C, PSI5 communications

- DUT-level voltage, current, or temperature monitoring

- GUI-based test programming and enterprise-level database management and automation

System Level Test and Burn-in Solutions

System Level Test (SLT) is a paradigm shift from traditional structural and functional testing. The device is tested in a complete, integrated system to evaluate its compliance against specified requirements. The system approach allows for higher and more cost-effective test coverage especially for multi-function and non-deterministic devices. It also brings new challenges like handling larger form-factors, integrating subsystems that interact with the device on a system level and additional stimulus and response capabilities like RF, protocol test or optical sensing.

With the multitude of devices and disciplines needed to do system level testing, solutions can be fairly complex and require different levels of customization. Aehr Test System brings a world class team of experts, 40+ years of expertise in burn-in and test and the agility to develop unique solutions given the right business case. We looking forward to learning more about your specific SLT test needs and bring our technology and platform solutions to address your test challenges.